In today’s fast-paced global marketplace, have you ever wondered what it takes to get a product from raw materials to your hands? Behind every item we use, from smartphones to daily essentials, lies a complex process known as Supply Chain Management (SCM). This intricate system, often working quietly in the background, ensures the seamless flow of goods—from suppliers to manufacturers, then to distributors, and finally to the consumer. But what makes SCM so essential in modern business?

For companies across various industries, effective supply chain management can be the difference between success and failure. By enhancing processes like sourcing, production, and distribution, organizations can reduce costs, improve quality, and even respond faster to consumer demands. This capability is especially important in an era where efficiency, flexibility, and sustainability aren’t just benefits—they’re necessities. But how do businesses optimize these complex networks to remain competitive?

In this article, we’ll dive deep into the fundamentals of SCM and explore why it’s a vital component for businesses of all sizes. Whether you’re interested in the key components of the supply chain, innovative models, or the cutting-edge technology driving change, this guide will provide insights into how supply chains work, why they matter, and what the future holds for this ever-evolving field. So, let’s embark on this journey to uncover the backbone of global commerce.

Actually a bird-eye view about supply chain management (SCM)

Let us take a moment to visualize how much effort goes into making or building something that you use every day, like your morning coffee. There are many steps in-between what is known as the supply chain, from sourcing the beans to roasting them, packaging to getting them into your local store. Whenever we go out to buy something, there is a well-organized process that we adhere to in order for the goods to reach us, i.e., supply chain management (SCM); in other words, it is a setup network in which everything works systematically so that whatever products you are looking for should reach you carefully and at an affordable price.

So what is SCM, and why is it important for business?

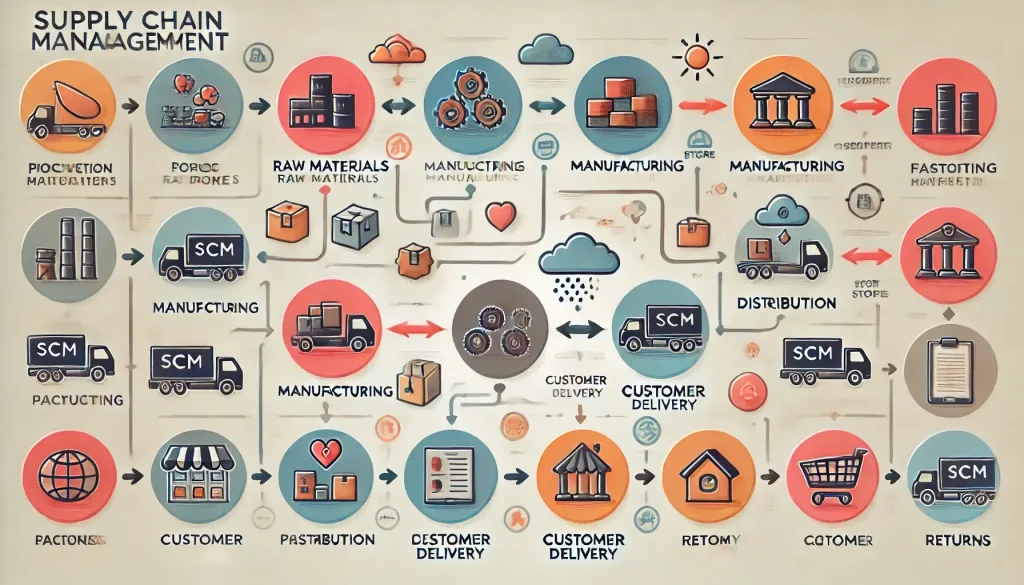

Fundamentally, SCM is the coordination and optimization of all steps in a product lifecycle, from raw materials to production to distribution and finally to your customer. And here is how each of them contributes:

Procurement and Vendor Management

The starting point of supply chain processes is sourcing raw materials and finding trustworthy vendors to source quality resources at a preferable price. At the heart of this is the relationship companies cultivate with their suppliers because these partnerships establish a foundation for all that follows.

Production and Manufacturing

For example, once raw materials are sourced, they enter the production phase, where they are turned into finished products. The key focus of this step is wide-ranging planning to keep processes free-flowing and cost in check, making it the core of supply chain management. Optimising production is important so that demand can be met, but there is no overproduction—avoiding high inventory costs and landfill waste.

Distribution and Logistics

After the product has been manufactured, bringing it to market is another hurdle. This is where distribution comes in, and especially more intricate logistics to make sure anything sold can actually be at the consumers’ doorsteps on time. That often comes down to effective distribution — having appropriate products in the desired locations oftentimes with a partner such as a third-party logistics provider or in-house logistics team.

Customer Delivery and Returns

Last but not least, the customer is part of this entire supply chain. Fast delivery is one of the most significant parts of customer satisfaction, but it really does not stop here. Returns, or reverse logistics, is one of the most crucial but often ignored aspects of effective SCM, as this field deals with how organizations handle items needing to return from consumers for repair, recycling, or resale—bringing the product lifecycle full circle.

Why Is Supply Chain Management So Important?

In a globalized economy, an efficient SCM is no longer an option but a requisite. Companies that optimize their supply chain can benefit in many ways:

- Cost Reduction: Minimizing waste, controlling resources, and optimizing logistics leads to a significant cost reduction for businesses.

- Enhanced Quality: SCM in retail helps the processes improve, so the customers get quality and reliable products.

- Quicker Delivery: Those companies that spend time optimizing their supply chain will have fewer delays, meaning they can deliver products faster—and this is a huge competitive edge.

- Improved Customer Satisfaction: Since customers are more likely to trust the brand when the product arrives on time and in perfect condition, SCM is an essential part of customer retention.

Whether it is the management of resources in an efficient manner, moving on to production, and finally delivery, supply chain management is one of the most essential parts of any business process today. So, the next time you sip on that straightforward cup of coffee, spare a thought for all the behind-the-scenes intricacies—and mastery—that brought it to bear!

Importance of Supply Chain Management in Modern Business

Some of you might be thinking about how SCM (Supply Chain Management) affects a complete business. Today, SCM not only has logistical value for firms but also helps in giving them a strategic advantage to be the players of the game or simply going extinct. SCM that is efficient will lower costs and boost impact on customer satisfaction level. But how does it do all of this?

Now let us understand some of the primary aspects that highlight the importance of supply chain management in modern-day markets:

1. Emphasizing Cost Minimization and Profit Maximization

Cost control is a must for any sort of business. An effective supply chain enables businesses to control stock, smooth manufacturing, and optimize distribution—all of these factors help lower residual costs. By analysing each level of the chain, companies avoid overproduction and loss due to dead stocks or buy huge storage space. Those savings add up to a more robust bottom line and better profit margins.

- Inventory Management—Good SCM helps companies maintain low inventory levels by ensuring they account only for what is demanded and required.

- Eliminating Waste: By improving processes, businesses are able to reduce waste at each level of process, starting from the source for raw materials up to end outputs.

- Distribution Efficiency— Intelligent distribution planning helps save logistics costs and enables the product to reach its desired market in-time.

2. Enhanced Customer Satisfaction

In today’s competitive market, consumers expect speed and reliability. SCM helps companies meet these expectations by enabling faster delivery times and improving product quality. When customers receive their products on time and in perfect condition, they’re more likely to remain loyal and recommend the brand.

- Reduced Lead Times: Efficient SCM reduces the time between production and delivery, meaning customers receive products when they need them.

- Quality Assurance: By closely monitoring every stage of production and sourcing high-quality materials, companies ensure that each product meets quality standards.

3. Increased Flexibility and Responsiveness

In these rapidly changing market conditions, flexibility is crucial. When a business has an agile supply chain, it can easily adjust to any changes in demand, respond to market trends, or even meet sudden challenges (i.e., shortages or open the flood gate for orders). Its ability only serves to help businesses remain ahead of the competition and give consistent customer satisfaction.

- Demand Forecasting: SCM offers prediction capabilities that help organizations prepare for the seasons of both maximum demand and sudden jumps.

- Responsive supply chains: a good SCM model facilitates swift changes in production and distribution to ensure that there are no bottlenecks or shortages of products for your company.

4. Sustainable Practices and Ethical Responsibility

As consumers become more environmentally conscious, businesses are focusing on sustainable and ethical supply chain practices. SCM allows companies to reduce waste, lower carbon footprints, and practice environmental social governance (ESG)—factors that are increasingly important to modern consumers. By sourcing responsibly and ensuring transparency, businesses build trust and enhance their brand reputation.

- Reduced Carbon Footprint: Through optimized logistics and reduced waste, SCM can significantly lower a company’s environmental impact.

- Transparent Sourcing: When companies work with ethical suppliers and track raw materials responsibly, they demonstrate commitment to social and environmental values.

Why It Matters More Than Ever

Supply chain management has transcended into a value creation activity that powers today’s interconnected world where simply moving products from point A to B is not enough. SCM is the backbone that enables sustainable growth and competitive advantage — from cutting costs to driving customer loyalty. Therefore, in the path of optimism for businesses, nothing is better than having a sustainable supply chain strategy.

When supply chains are managed effectively, they not only provide logistical support; they empower companies to take charge of their industries by adapting to changing customer demands and functioning appropriately as society becomes ever more rapid time-wise but also ethically driven.

Key Components of the Supply Chain Process

Examining each step in the supply chain process is key to understanding how SCM generates value. Each element is a part of an interconnected unit, establishing product movement from conceptualization to consumer use. Now, what exactly are these major components that pull together to create a cohesive, streamlined supply chain?

We will get deeper into the prime components that SCS involves and their individual contributions here:

1. Sourcing and Supplier Management

Every product starts with sourcing raw materials. Finding reliable suppliers is crucial; they’re the foundation of the supply chain, and the quality and consistency of materials can directly affect the final product. Effective supplier management involves building strong relationships, negotiating good terms, and ensuring a steady supply of resources.

- Choose Reliable Suppliers: This is where quality assurance starts. Sourcing appropriate suppliers means sourcing the right kind of products that meet industry standards and customer expectations.

- Cost & Terms: Negotiation In the case of good supplier management, cost is controlled and so are your profit margins.

- Strong Partnerships: A strong supplier relationship means improved collaboration, smoother processes and a more resilient supply chain.

2. Production and Manufacturing

After procuring materials, production comes next, converting them into finished goods. The place where innovation and efficiency come into effect is in this stage, as production processes dictate costs, quality, and delivery speed.

- What Effective Manufacturing Processes Look Like: A streamlined process cuts out waste and ensures goods are manufactured to specification, providing time and dollar savings for an organization.

- Quality Control: Having quality checks during the production process ensures that the quality of the final product is up to mark, which means there are fewer returns and complaints from customers.

- Strategies for scalability: The right SCM strategy allows firms to scale production as needed according to demand, mitigating shortages and preventing overproduction.

3. Inventory Management

Great supply chains always have a barometer on how their inventory is doing. Inventory management covers stock control to demand planning, execution, and making sure products are available based on that request. Excess inventory reduces capital flow, while shortages and delays come from too little.

- Demand forecasting: another major factor is predicting demand accurately to avoid over- or under-inventory of goods, especially at peak seasons or for sudden changes in demands.

- Warehouse management: It covers the best packing and storing of the inventory to get its minimum cost of transportation as well as maximum order completeness.

- Meaning of Inventory Optimization: In SCM, many of the advanced tools allow you to optimize inventory levels so as to have equality between demand and supply without incurring too much holding cost.

4. Distribution and Logistics

After product is done, it needs to be transported effectively towards the end consumer. This way of getting the final product from a shelf in your store to your customer is considered distribution and logistics. Providing that it matches distribution and logistics, that means the end product will arrive at the perfect spot at the precise time and in excellent condition?

- Logistics Planning: You have to plan everything from routes to which carriers you would choose and what shipping options you would be using, i.e., ground, overnight, express, or cost-effective.

- Delivery Tracking: Modern SCM allows for tracking of shipments in real-time, providing transparency and enabling customers to track their packages.

- Warehouse and Fulfilling: Setting a responsible fulfillment center produces most of the work associated with packaging and provides simple, from proper quarters to making certain customer supplies have been accurate and beginning received fast.

5. Returns Management and Customer Services

Delivery is just the beginning of a well-rounded supply chain. However, returns management is an integral part of SCM, and it influences customer satisfaction and brand loyalty. With proper handling of returns, a company can minimize losses, reclaim assets, and keep the customer happy.

- The Returns Process: A smooth and efficient return process will keep customers happy, more so as these also involve replacements or repairs.

- Return and Repair: Depending on the condition of the product, they may offer to repair it, sell it, or simply recycle it so that you no longer contribute waste but sustainably attempt to reduce your carbon footprint.

- Customer Service: The trust that is built through prompt and clear communications during the returns process leads to stronger future loyalty.

The Role of Each Component in Building a Strong Supply Chain

Each stage in the supply chain process is essential for delivering a high-quality product to the consumer. From sourcing to final delivery, each component adds unique value, creating a chain that’s efficient, cost-effective, and customer-centric. Businesses that optimize these key components can achieve greater flexibility, reduce waste, and enhance overall customer satisfaction—building a competitive edge in the marketplace.

In a world where customers demand fast, reliable service and businesses are constantly looking to innovate, these core elements of supply chain management form the backbone of successful operations. By focusing on each stage, companies can create a supply chain that not only meets but exceeds market expectations.

Emerging Trends in Supply Chain Management

Supply Chain Management (SCM) is one of the most dynamic worlds driven by technological advancements, changing consumer expectations, and an increasing focus on sustainability & circular economy. Companies that have kept pace with these trends have found themselves holding a significant competitive advantage. What, then, are the key trends doing the most to define supply chains as they exist in our modern world, and how can enterprises capitalize on these?

Now, let us take a close look at some of the important trends related to SCM and how they are changing the operational capabilities of the business.

1. The Technology Of Digital Transformation And Big Data Analytics

SCM is only possible today in the modern world due to technology. Thanks to mighty data and analytics tools, businesses can now make more intelligent decisions based on data. Data insights offer visibility and accuracy, enabling companies to improve efficiency and reduce costs—everything from demand prediction to logistics optimization.

- Predictive Analytics:Companies are using big data to get a better idea of what people want. This helps them avoid making too much stuff and cut down on waste from extra inventory.

- One of the key things about supply chain management software is real-time tracking. Basically, these advanced systems help us keep things open and clear in our supply chain and make it easier to react quickly when we need to.

- Automated Reporting: Automation makes it a lot easier to collect and analyze data. It helps managers see what’s happening in the entire supply chain in real-time.

2. Sustainability and Environmental Social Governance (ESG)

As sustainability becomes a higher priority to more consumers, businesses are being pressured into sustainable practices. Using Environmental Social Governance (ESG) principles in supply chain management is a great way to boost your brand’s image. Plus it helps cut down on waste and can spark some fresh ideas along the way.

- Green Logistics: You can see that green logistics is now the norm for companies looking to cut down on their impact on the environment. They’re picking fuel-efficient ways to get around and opting for eco-friendly packing materials. It’s great to see these choices becoming popular!

- Sustainable Sourcing: Businesses want to team up with suppliers who really know how to take care of their resources and are using eco-friendly methods.

- Circular supply chains: This trend focuses on reusing materials and creating products that last longer. All of this helps build a more sustainable economy by cutting down on waste.

3. More Adaptiveness with Flexible models of supply chain

The pandemic exposed the world to varying degrees of agility and resilience. Sometimes demand goes through the roof or suppliers run into issues, but supply chains that can roll with the punches and adapt to those changes are set for whatever surprises may pop up.

- Flexible Sourcing: More suppliers mean quicker resource shifts, mitigating delays and bottlenecks.

- Flexible Manufacturing: Agile production helps businesses adjust their operations fast based on what people want. This way, they can lower their inventory and cut down on costs.

- Variegated Logistics Alternatives: Companies are using different shipping options so they can still get their products where they need to go if one way of transport isn’t available.

4. Adoption of AI and ML

This has created opportunities for AI and machine learning products in businesses and supply chains since they can take care of a lot of tricky tasks. For example, they help with managing inventory, support human agents, and automatically solve ticket issues. This all helps to cut down the time it takes for customers to get help. SCM systems with AI-driven insights to automate time- and error-prone functions.

If you take a look at previous sales data, market trends, and when things are typically busy, AI tools can use some smart math to help predict what people are going to want in the future.

Here are a few ways to help the retail business skyrocket: First up is inventory optimization. By figuring out which items will fly off the shelves you can cut down on storage costs.

Better Decision-Making: AI analyzes huge amounts of data and allows supply chain managers to make informed decisions more efficiently.

5. Increased Emphasis on Customer Experience

Founded in Customer Satisfaction — In the current market, we get everything on-demand and hence supply chains are shifting towards a more customer-oriented approach. Consumers are demanding quality products but also the ability to get fast, transparent and reliable service. A customer-focused SCM process has the potential to drive loyalty and ensure that businesses stay ahead of the competition.

- Quicker Delivery Alternatives: The rapid shipping solutions are the brand-new norm, which can deliver your order in the very same or next-day time. Good SCM makes this kind of process possible without having to compromise on quality.

Staying Ahead in the Changing SCM Landscape

Adapting to these trends isn’t just about keeping up; it’s about staying ahead. As companies embrace digital transformation, prioritize sustainability, and strive for greater agility, they’re setting new standards in supply chain management. Forward-thinking businesses are those that integrate these trends into their strategies, creating a supply chain that’s not only resilient but also responsive to customer needs and environmentally responsible.

By staying informed and adaptable, companies can build a supply chain that not only withstands today’s challenges but also drives long-term growth and success in a rapidly evolving world.

Benefits of Effective Supply Chain Management

A well-structured supply chain management (SCM) system can be transformative for any business, boosting everything from profitability to customer satisfaction. But what are the real advantages of effective SCM, and why should companies prioritize it? Let’s dive into some key benefits that make a strong SCM strategy a game-changer.

1. Cost Reduction and Increased Profit Margins

One of the most immediate benefits of efficient supply chain management is cost reduction. By streamlining processes, optimizing inventory, and managing suppliers effectively, companies can cut down on unnecessary expenses.

- Lower Inventory Costs: Effective SCM reduces excess inventory, which saves on storage costs and minimizes the risk of product obsolescence.

- Reduced Production Costs: When every part of the supply chain is optimized, production becomes more efficient, cutting down on wasted materials and labor costs.

- Enhanced Negotiation with Suppliers: Good supplier relationships often lead to better terms and pricing, helping to lower production expenses and increase profit margins.

2. Improved Customer Satisfaction

Modern consumers value products of decent quality but also on-time and reliable delivery. As a well-oiled machine, supply chain equates fast delivery and the minimal disruptions to products reaching out to customers and hence customer experience.

- Timely Deliveries: With efficient SCM processes, companies deliver products on time and even improve customer expectations.

- Transparent tracking: Many supply chains introduce real-time tracking that improves transparency and gains customer trust.

- Manage Returns Effectively: When customers get a smooth returns process to return or replace any good, it encourages them to further accept goods from the same brand, which raises their loyalty.

3. Greater Agility and Flexibility

In the dynamic market, flexible approach are imperative. Companies with a flexible and responsive supply chain can quickly adjust to changes in demand, supply disruptions or other unplanned events.

- Adapting To Demand Shifts in Minutes: Companies can match inventory levels to changing demand based on the data and predictive analytics.

- Effectively Manages Supplier Relationships: A well-functioning SCM means that the company can easily switch suppliers or adjust sourcing strategies without incurring huge costs due to delays.

- Decreasing Lead Times: Quicker lead times help firms get their items into the industry faster, offering all of them an upper hand.

4. Better Collaboration Across Departments

Effective SCM promotes collaboration not only with external suppliers but also within a company. When all departments are aligned— from procurement to sales—it becomes easier to achieve common goals and optimize the overall business operation.

- Smoother Communication: With a cohesive SCM strategy, departments work together more effectively, reducing bottlenecks and misunderstandings.

- Aligned Goals and Metrics: When every team understands and works toward the same SCM objectives, there’s greater synergy and productivity.

- Improved Forecasting and Planning: With better visibility into supply chain data, departments can plan ahead more accurately, aligning resources to meet demand.

5. Risk Mitigation and Supply Chain Resilience

Things like natural disasters and shortages are really putting pressures on supply chains nowadays. So the best way to tackle this is by making sure your supply chain runs smoothly. Good supply chain management helps businesses spot and understand risks tied to demand, supply, or transport problems. That way, they can come up with solutions before things start to hurt their profits.

- Proactive Risk Management: Being able to determine whether the supply chain has vulnerabilities can also provide companies with the option of implementing contingency plans.

- Diversification of Suppliers: Multiple supplier working lowers dependence on a single source, and in case one source fails, it is easier to keep the operation going.

- Faster Response to Crisis: SCM leads to optimal performance and enables the better management of any crisis.

Why Invest in Supply Chain Management?

In today’s competitive market, the benefits of a well-executed supply chain management strategy are too valuable to overlook. Not only does SCM drive cost-efficiency and profitability, but it also strengthens customer relationships, enhances adaptability, and safeguards against risk. By focusing on these key benefits, businesses can create a resilient, responsive, and customer-centric supply chain that fuels growth and success well into the future.

For companies looking to build a competitive edge, prioritizing SCM is not just a smart move—it’s a necessity.

Key Components of an Effective Supply Chain Management System

Creating an effective Supply Chain Management (SCM) system involves more than just managing the flow of goods. It’s about coordinating complex processes, ensuring quality, and aligning every step with business goals. So, what are the essential components that make up a successful supply chain? Let’s break down the core elements that are crucial for building an efficient SCM system.

1. Sourcing and Procurement

Sourcing — the earliest stage of any supply chain — covers everything from identifying suppliers to contract negotiation. The goal? To provide availability of high-quality & economical materials as per the production requirements.

- Supplier Selection: They need to get good suppliers who provide materials with quality. Maintaining good rapport with suppliers and communicating openly reduces the amount of time required for quality management or negotiating costs.

- Contract Negotiations: Good contract terms can help companies lower overall costs whilst allowing greater control over prices and inventory.

- Sustainable sourcing: More and more companies are focusing on sustainable sourcing these days. They’re making sure to pick suppliers who care about the same environmental and social goals as they do.

2.Inventory Management

Keep stockouts or overeagers stocked for sustainable revenue earning and expense variance by effective management of assets. The right inventory strategies help companies always have the correct amount of product on hand.

- Demand Forecasting: Using big data and predictive analytics helps companies guess demand better. This way they can cut down on extra inventory and save on storage costs too.

- Just in Time (JIT) Inventory: The JIT inventory is a method in which you maintain the very minimal amount of stock and order only when required. It may lower some storage costs while delivering fresh products.

- Safety Stock: A lot of companies keep some extra stock on hand just in case they face a sudden jump in demand. This way they can avoid running out of products when they need them the most.

3. Production and Manufacturing

This component is related to the transformation of raw materials into finished goods. Good manufacturing practice improves productivity, reduces waste and can deliver product to meet customer needs in a timely manner.

- Quality assurance: Quality has to be consistent for customer satisfaction and brand value. By performing rigorous QC at every stage, you can avoid expensive recalls.

- Lean Manufacturing: Lean practices work to cut down on waste in manufacturing, like using fewer materials, minimizing labor, or saving time. This helps lower costs and boosts production.

- Flexible Manufacturing: Some companies have a laid-back approach when it comes to making their products. This way, they can quickly switch between different items or adjust production based on what people are looking for in the market.

4. Logistics and Distribution

The logistics itself includes planning and execution to deliver goods from one point to another. Having a well-defined logistics strategy will ensure that the products are delivered to customers quickly and at minimum cost.

- Transport Mode: Choosing the best way to transport things, whether it’s by air, sea, or land, is super important for saving money on logistics and for products that need to get there quickly.

- Warehousing: Good warehousing helps save time, cut down storage costs, and reduce mistakes in order processing. It makes sure there’s a smooth flow from making products all the way to getting them to the customer.

- Real-Time Tracking: Manufacturers with good tracking systems can now easily keep tabs on their shipment status and step in to help if any issues pop up.

5. Returns Management (Return Logistics)

Returns management is an integral part of SCM but one that a lot of business owners often overlook. However, an effective return process can make for happier customers, less wastage, and even some reclaimed value.

- Return Policies: Good return policies can really help build trust. When customers feel confident about returning items, they’re more likely to come back to your store.

- Refurbishing Products: In an effort to decrease waste and enhance cost recovery, some returns can be refurbished and sold again.

- Managed Return Processing: Good reverse logistics can really cut down on the time and effort it takes to handle returns. This helps make the return process easy and smooth for your customers.

6. Data & Technology Integration

For such SCM, the right setup is essential when we are going tech-savvy. Whether it be AI-driven analytics or automated orders, technology allows for rapid and informed decisions.

- Supply Chain Software: ERP systems are great tools that help combine and manage data throughout the whole supply chain. They give you one clear view of everything happening in your operations.

- Automation and AI: Automation helps you get repetitive and number-based tasks done faster. On the other hand, AI steps in to improve how accurately you can forecast things by using smart predictions which boost your decision-making skills.

- Use blockchain for transparency: Blockchain can enhance traceability — and especially for industries that need authenticity and transparency.

Why These Components Matter

A good supply chain management plan that includes these parts not only makes things run smoother but also makes customers happier, cuts down on expenses, and helps you bounce back from any hiccups. Whether you’re kicking off your supply chain or sprucing up what you already have, paying attention to these important points can help you build a system that’s both quick to react and strong.

In today’s fast-paced, competitive market, integrating each component seamlessly can make all the difference in achieving long-term success.

Challenges in Supply Chain Management and How to Overcome Them

While an effective Supply Chain Management (SCM) system offers numerous benefits, it also presents a variety of challenges that businesses must navigate. Understanding these obstacles is essential for building resilience and ensuring smooth operations. What are the common pitfalls in SCM, and how can companies tackle them effectively? Let’s explore some of the most significant challenges and actionable strategies to overcome them.

1. Supply Chain Disruptions

Sometimes things can really mess up supply chains. Natural disasters, political issues, or even surprises like a pandemic can cause delays in deliveries and drive up costs. How can businesses be ready for such uncertainties?

- Assess Risks: Periodically evaluate risks in your supply chain, e.g. supplier reliability, political situations in producing countries. By knowing where the hot spots are, you can plan ahead.

- Supplier Diversification: It can be risky to depend on a third party for your inventory. Having a mix of suppliers can really help reduce the effects of interruptions, especially when they’re due to things like weather or location. If one supplier runs into trouble, there’s a good chance another one can fill the gap.

- Contingency planning: It’s a good idea to have solid backup plans ready for different situations. This includes having ways to source materials differently and a plan for emergencies.

2. Dealing with Problems of Inventory Management

Finding that sweet balance where you have enough stock to meet customer needs but not too much to spoil can be a challenge. How can you better manage your inventory?

- Demand forecasting: Use big data tools and analytics to enhance your demand forecasting. Improving your predictions can help you better manage inventory levels.

- JIT Inventory: Establish a Just-in-Time (JIT) stock process to decrease surplus inventory. This minimizes storage charges and allows you to have a fresh delivery of your stock.

- Frequent Audits: Audit your stock regularly to pick out slow-moving products and adjust purchasing accordingly.

3. Technological Integration

With the evolving technology, integrating new systems into the existing one is often a big hurdle. What should businesses do to facilitate a smoother transition during new SCM technologies?

- Training and Support: To train the staff on-train of new technologies. Go with the flow. Ensure that everyone knows how to work with the systems, which will generally help in keeping resistance against new change low.

- Choosing the Right Tools: Select SCM tools that are compatible with the existing systems you already have in place. It minimizes disruptions and improves efficiency overall.

- Have an Eye for Improvement: Instill a culture of continuous improvement. Assess your technology periodically and update when needed in order to keep up with market competition

4. How to Manage Your Relationships With Suppliers

A solid network of suppliers is crucial to having a successful supply chain. However, keeping up these relationships is quite difficult. The question, then, is, What can you do to improve collaboration?

- Open one: Keep an open communication with your suppliers. When possible, step in to redirect issues before they explode.

- Vendor Management Strategy: Consider treating your suppliers as partners, not merely vendors. Get them involved on the decision side and work together on quality and productivity initiatives.

- Supplier Performance: periodic assessments by implementing performance metrics. Good performance should be recognized and rewarded, as this helps maintain high standards from the suppliers.

5. Compliance with the Regulations of Regulatory Body and Sustainability

Complying with the regulations and sustainability norms is gaining a lot of brawl. How can suppliers guarantee compliance while at the same time making efforts for sustainability in their supply chain?

- Stay Updated: Make sure to be updated about the shifting regulations in your field. Training staff regularly is a great way to assist with compliance requirements but also ensure everyone understands sustainability better.

- Sustainability: Make sustainability a part of your sourcing and manufacturing. Selecting sustainable materials and reducing waste, for example.

- Transparency and Reporting: Acknowledge your sustainability. Some form of regular supply chain environmental impact reporting not only increases trust but also brand equity.

6. Customer Demand Variability

The changes to demand from customers pose a significant challenge in SCM. Well, how do companies cope with this variability?

- Flexibility in Production: Adopt flexible manufacturing systems that rapidly adjust to shifting demand. That could mean different production quantities or even a complete product line transition.

- Consumer insights: An example is to use consumer insights and market research to help you identify demand trends better. You can accordingly tailor your strategies to achieve a better response.

- Agile Supply Chain Practices: Implement agile practices to facilitate quick changes in response to live data This guarantees that you can pivot your supply chain effectively with demand changes.

Conclusion: Embracing Challenges for Greater Resilience

In conclusion, while challenges in supply chain management can seem daunting, they also present opportunities for growth and improvement. When businesses tackle challenges directly with smart strategies they can strengthen their supply chain and boost efficiency while keeping customers happy. Keep in mind that every problem is an opportunity to get creative and adjust your approach. Having this mindset is super important if you want to do well in today’s ever-changing market.

Conclusion: Navigating the Future of Supply Chain Management

As we wrap up our exploration of supply chain management, it’s clear that navigating this complex landscape requires not only strategic thinking but also adaptability and innovation. Have you considered how your business can leverage the insights we’ve discussed to enhance your supply chain processes? Building a strong supply chain involves a bunch of different things like handling risks dealing with suppliers and using the latest tech while also being sustainable. Each of these pieces is super important to make sure everything runs smoothly.

The challenges we face in SCM today are not just hurdles; they are opportunities for growth and improvement. By adopting effective practices, such as flexible inventory management and robust demand forecasting, you can better position your company to respond to fluctuations in the marketplace. Are you ready to transform your approach to supply chain management and lead your industry in efficiency and sustainability?

Remember, the key to a successful supply chain lies in continuous improvement and collaboration. Working with your suppliers like they’re your partners, keeping up with new rules, and using the latest tech can really help you stand out in a tough market. As you reflect on the insights shared, think about the steps you can take to enhance your supply chain operations.

So, what will your next move be? The future of your business depends on the strength and agility of your supply chain. By taking proactive measures today, you can not only overcome challenges but also thrive in a constantly evolving landscape. Embrace the journey, and let’s make supply chain management not just a function of your business but a strategic advantage.